5151+ reviews

Order by 16:00 for same day shipping

14 days return

EN

Individual

Business

Filters

Price

to

Printed circuit boards

Printed circuit boards are the heart of almost every electronic system. They provide secure mounting of components and enable reliable connections. Unlike breadboards, which are useful for temporary testing, printed circuit boards offer a permanent and robust solution. A breadboard is mainly used in the early stages of a project. It allows you to experiment quickly. You insert components into the holes without soldering. This makes it easy to change something or start over. But once your design works, you want something more permanent. Then solderable printed circuit boards such as perfboards or veroboards are the logical step.

11 products found

Sort by:

What types of printed circuit boards are there?

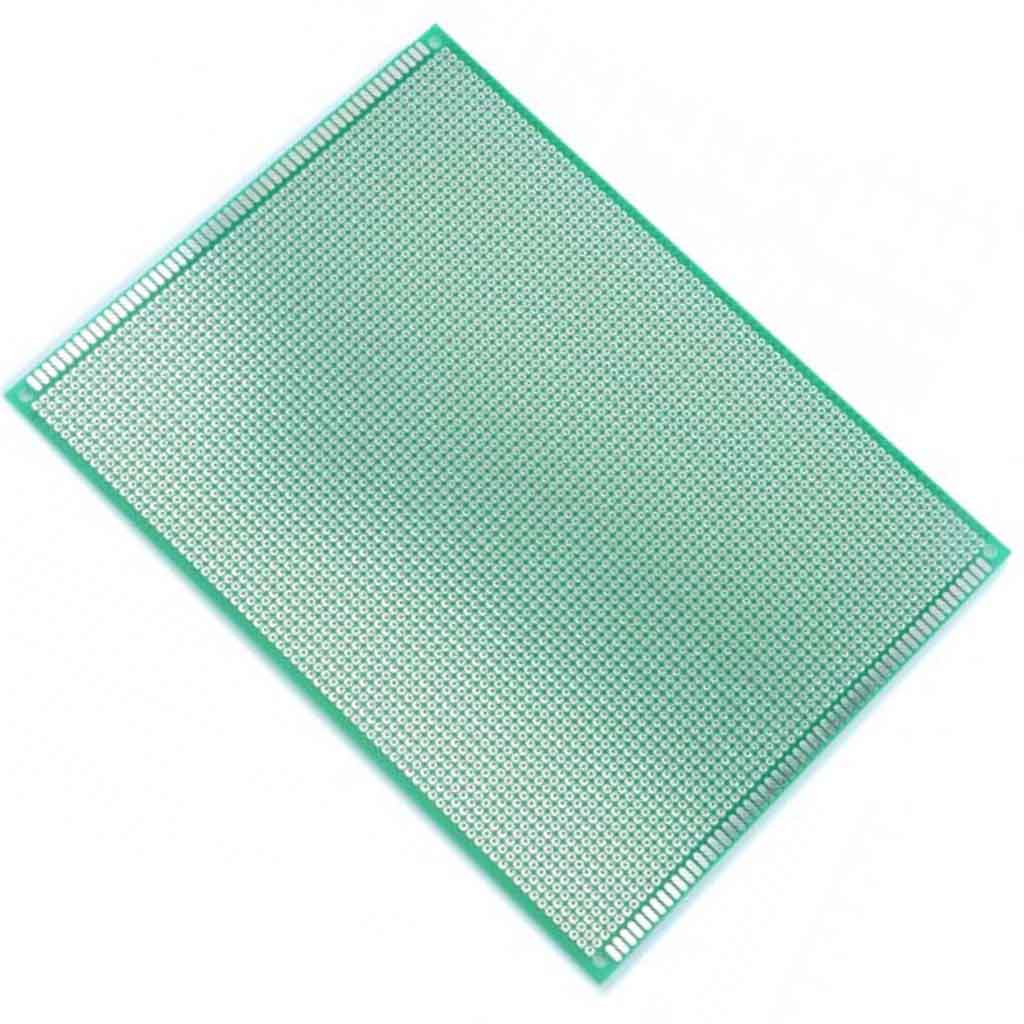

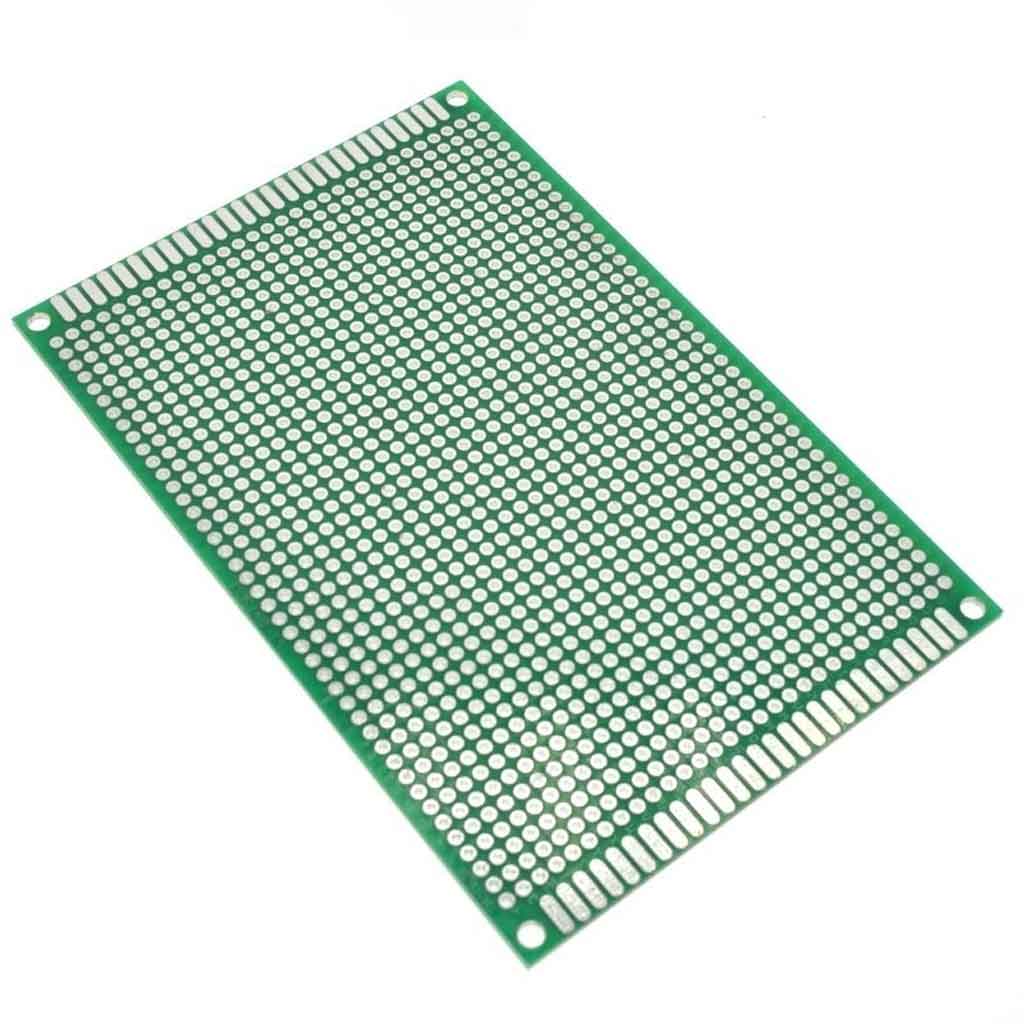

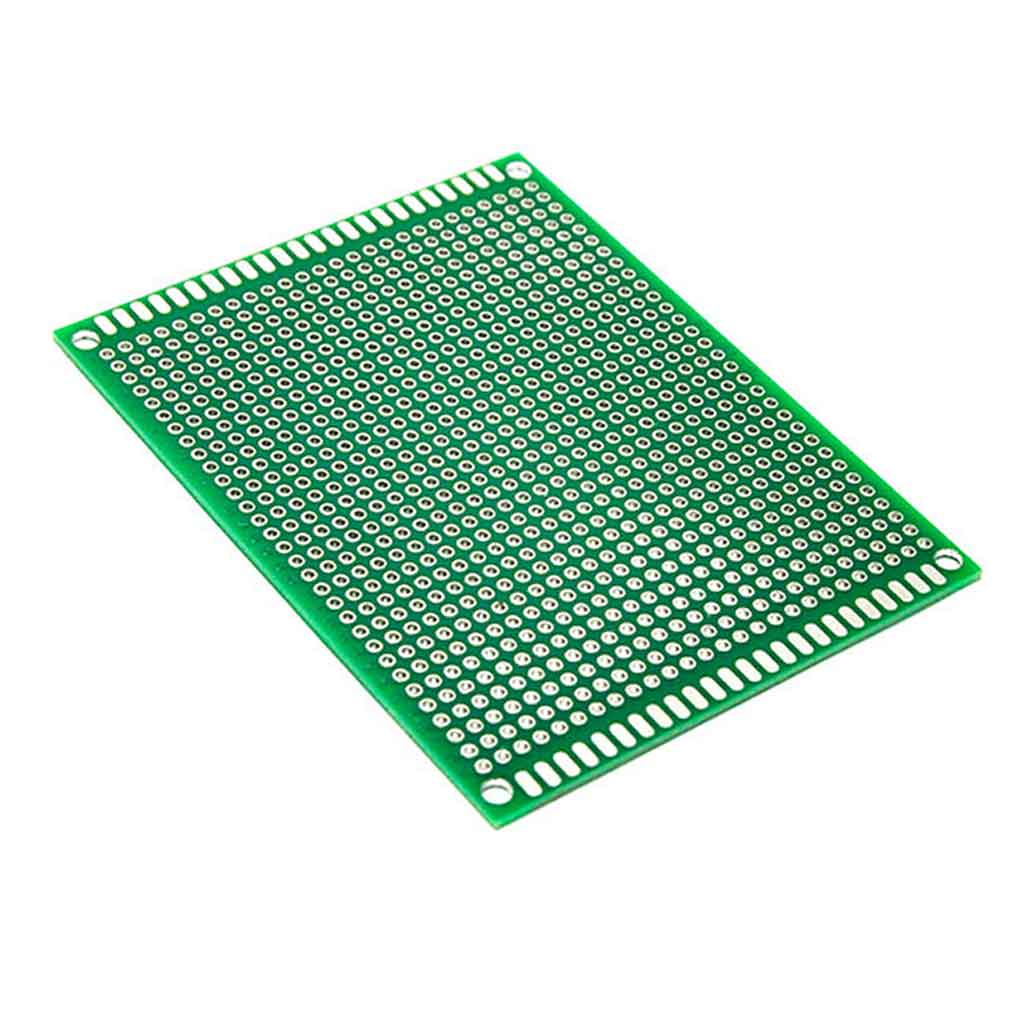

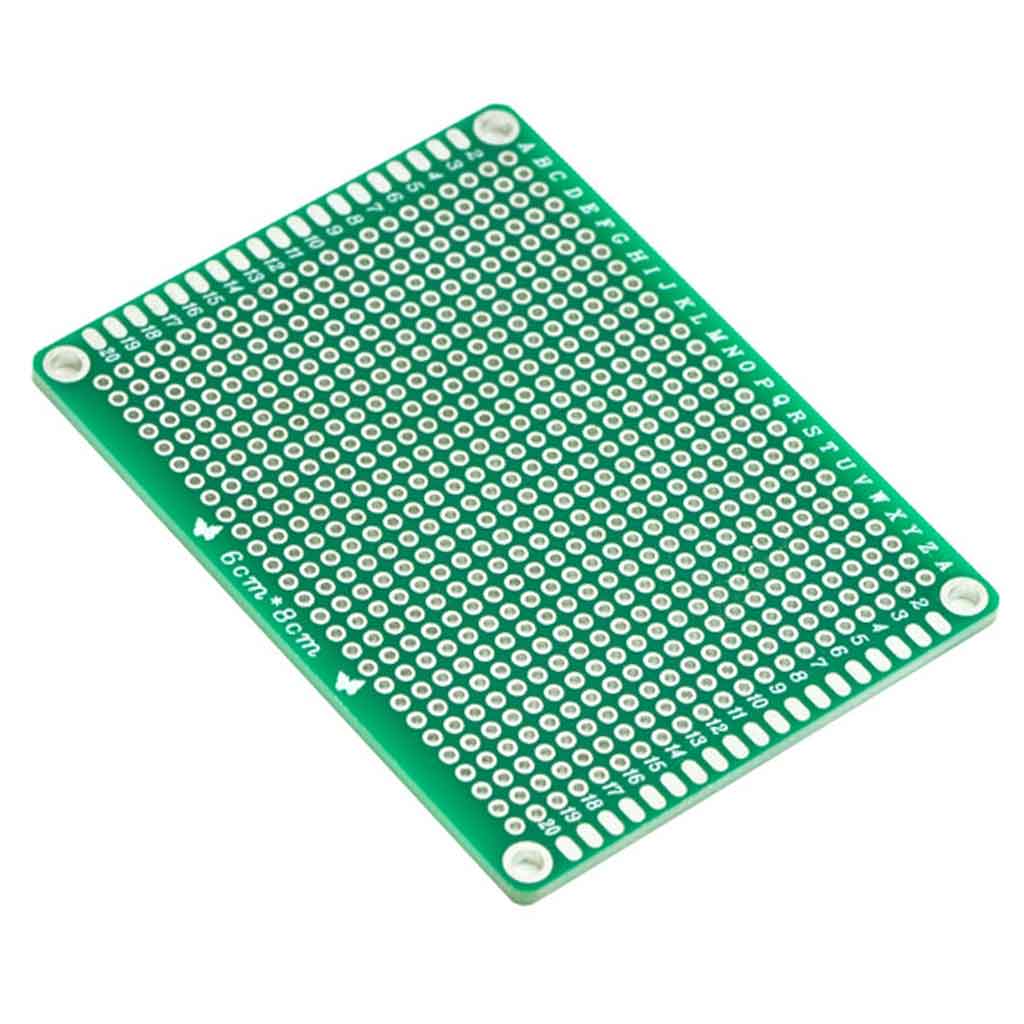

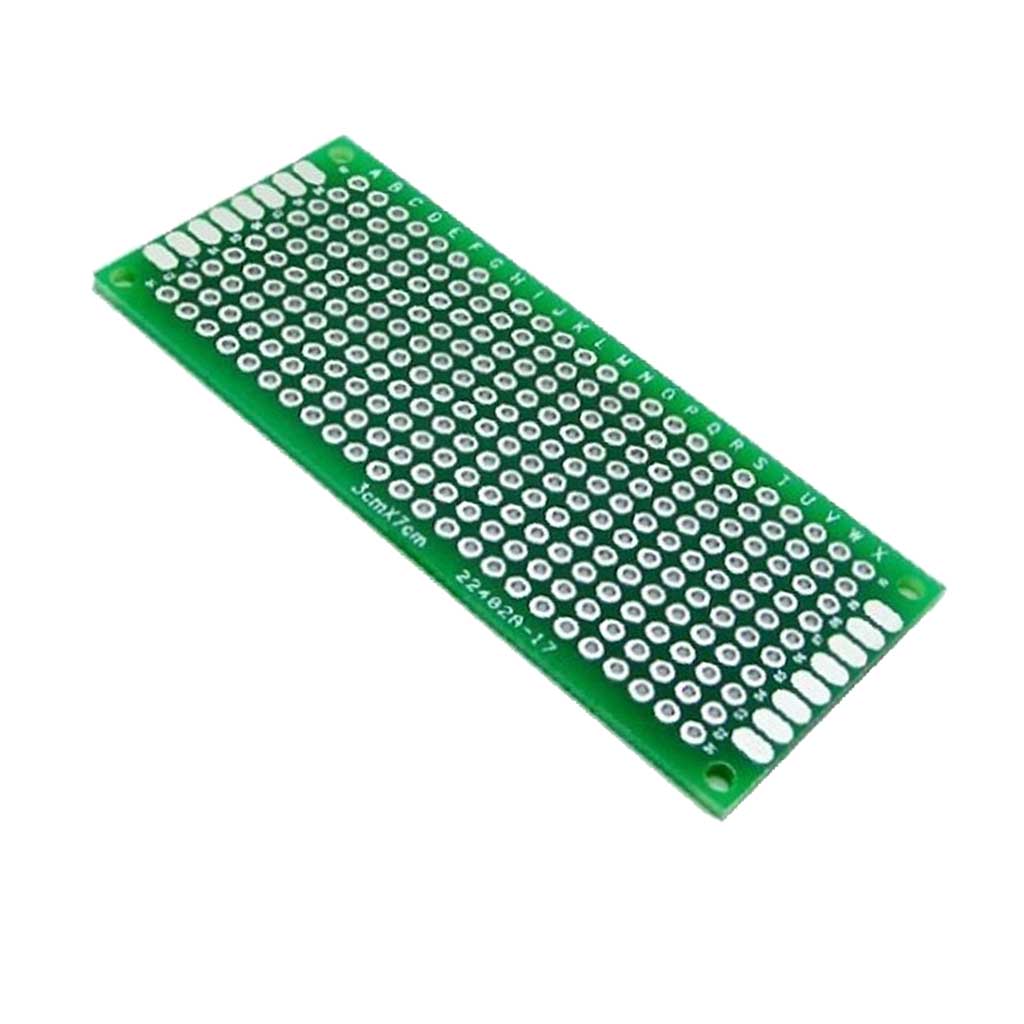

There are different types of printed circuit boards. Each type has its own application. Perfboards have a grid with loose holes. You place components and connect them with wire or solder. This gives a lot of freedom, but requires a precise approach.

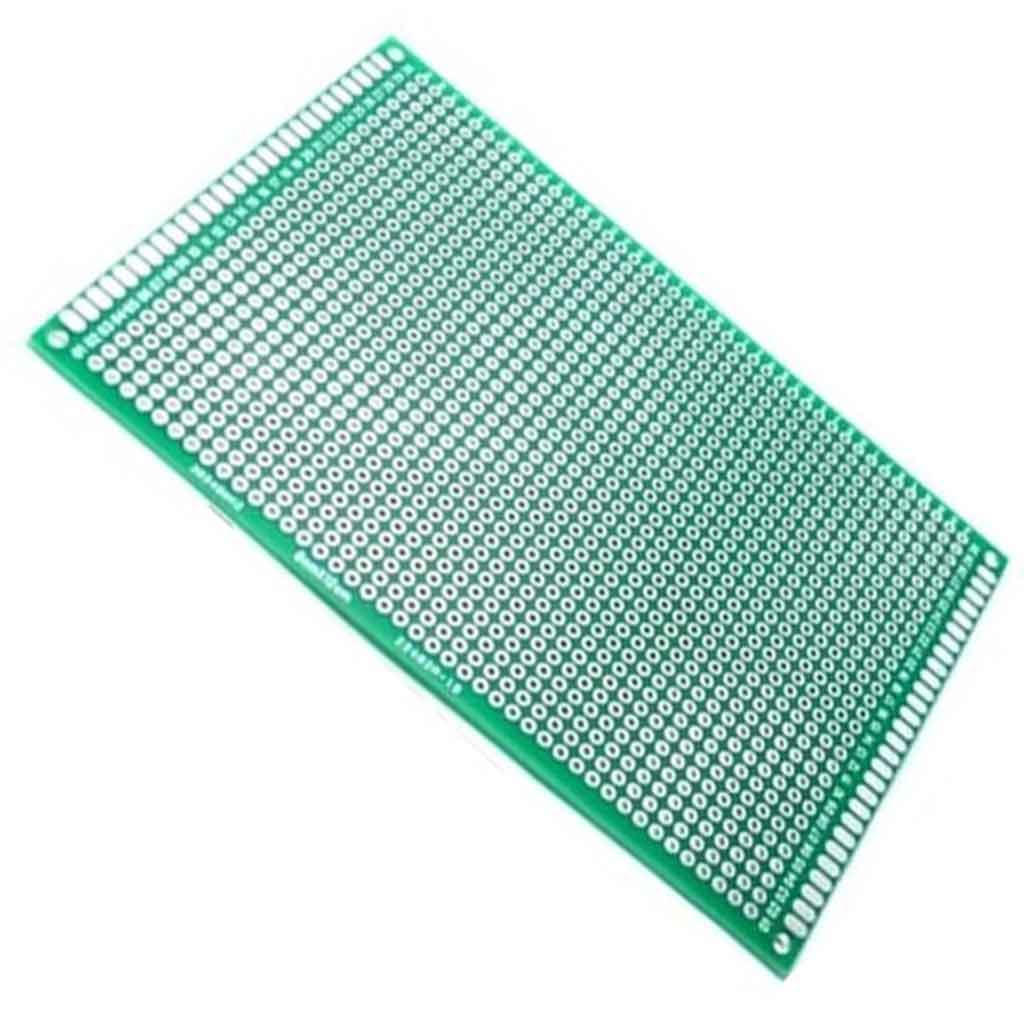

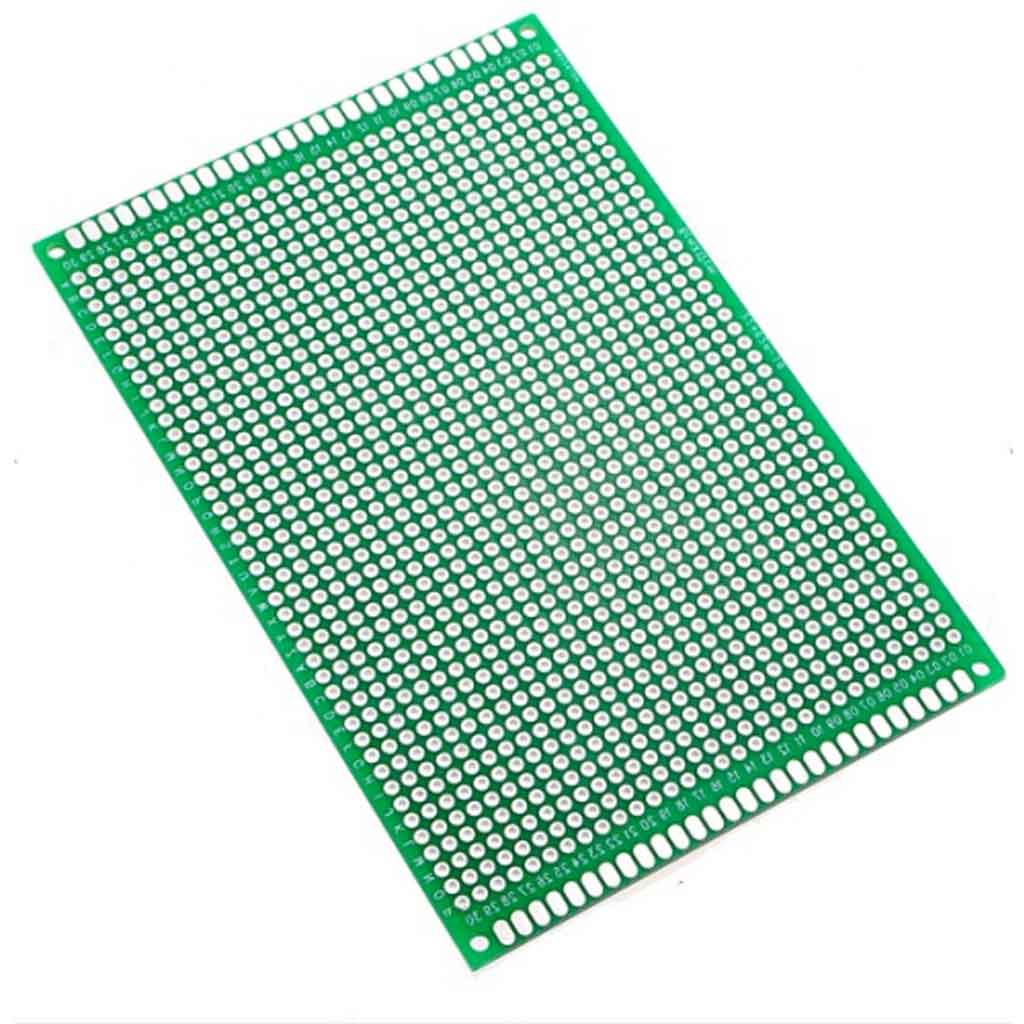

Veroboards are similar to perfboards, but contain horizontal copper traces. As a result, some connections are already present. This speeds up the construction of simple circuits. However, you have to be careful where you break or adjust connections.

For advanced projects, there are PCBs (Printed Circuit Board s ). These have etched tracks according to a fixed design. They are accurate and reliable. You often see them in end products and commercial devices.

Within our range you will find all kinds of printed circuit boards. From simple universal PCBs to boards with connections for Arduino, Raspberry Pi or ESP32. These connect seamlessly to the pin layout of your development board.

How to choose the right printed circuit board?

When choosing, first look at the purpose of your project. Is it temporary or permanent? For temporary setups, a Breadboard is suitable. Do you want to build something that will continue to work? Then choose a solderable printed circuit board.

Also consider the available space. Small applications require compact boards. Larger circuits with many components require more surface area. So choose a format that fits your design and housing.

The material also plays a role. Most printed circuit boards are made of FR4. This is glass fiber that provides strength and a long life. For lighter applications there are also cheaper materials, but they are less robust.

Finally, consider compatibility. Some boards are specifically designed for popular microcontrollers. They have connections in exactly the right places. This saves you a lot of measuring and prevents errors.

Tips for working with printed circuit boards

A good preparation is half the battle. Start with a clear diagram. Draw your circuit and check the connections. This will prevent confusion during construction.

Make sure you have a tidy workspace. Lay out all your components. Use colors for your wires so you can distinguish between power, ground, and signals.

When soldering, use a good quality soldering iron. Set the temperature correctly. Use fine solder with flux and ventilate your work area well. Soldering requires patience and precision. Heat each contact point briefly and add solder as soon as the metal is hot enough.

Test your circuit regularly during construction. This way you will discover errors in time. Use a multimeter to measure connections or detect short circuits.

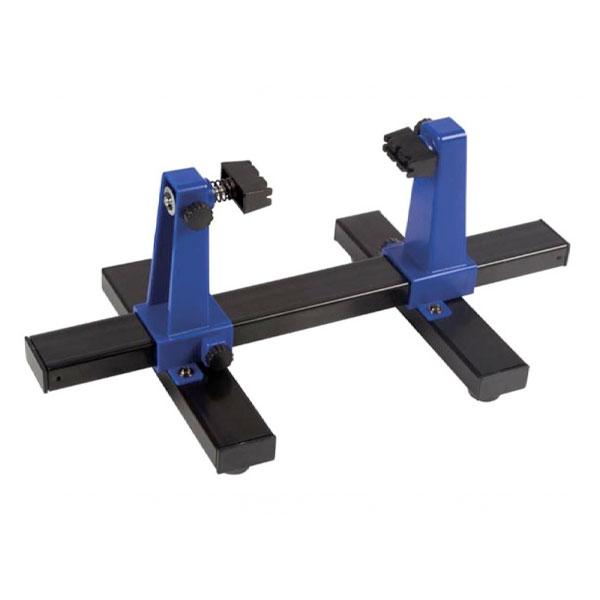

Finish your project with handy accessories. Headers, pinstrips, spacers and screws help you mount your circuit firmly and clearly. At Elektronica Voor Jou you will find everything to complete your printed circuit board project.