5183+ reviews

Order by 16:00 for same day shipping

14 days return

EN

Individual

Business

GPIO Project 8 - Sound Controlled Motor

Beginner

30 Minuten

113,90

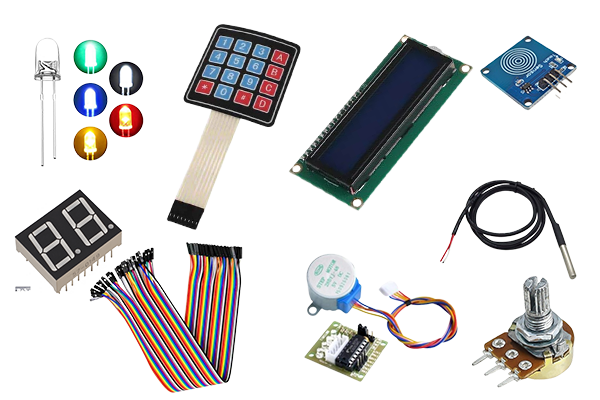

In this project you will learn how to use a sound sensor (found in the GPIO kit ) to control a motor. The sound sensor detects sounds (e.g. a clap) and sends a signal to the Raspberry Pi , which activates a motor.

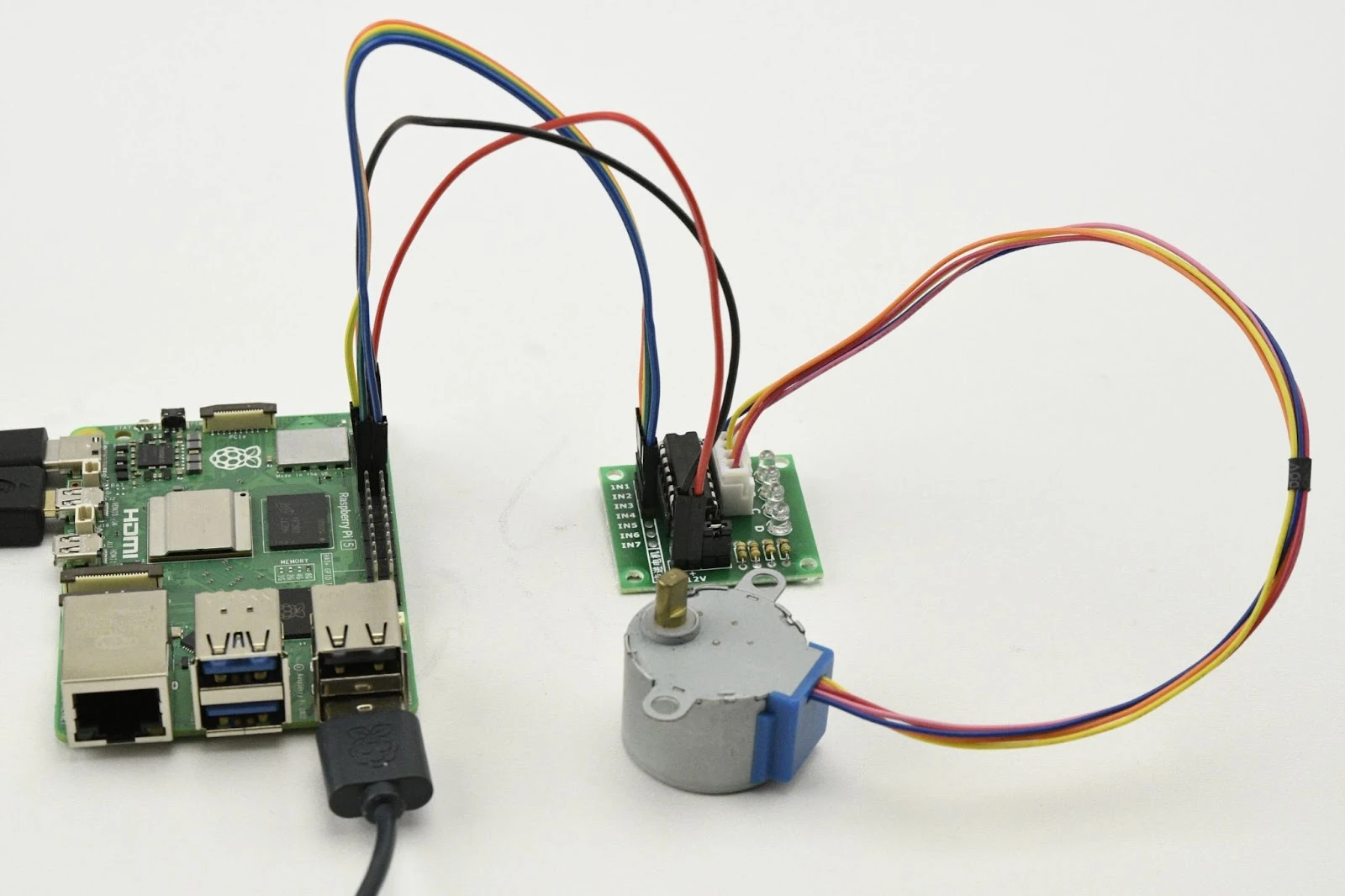

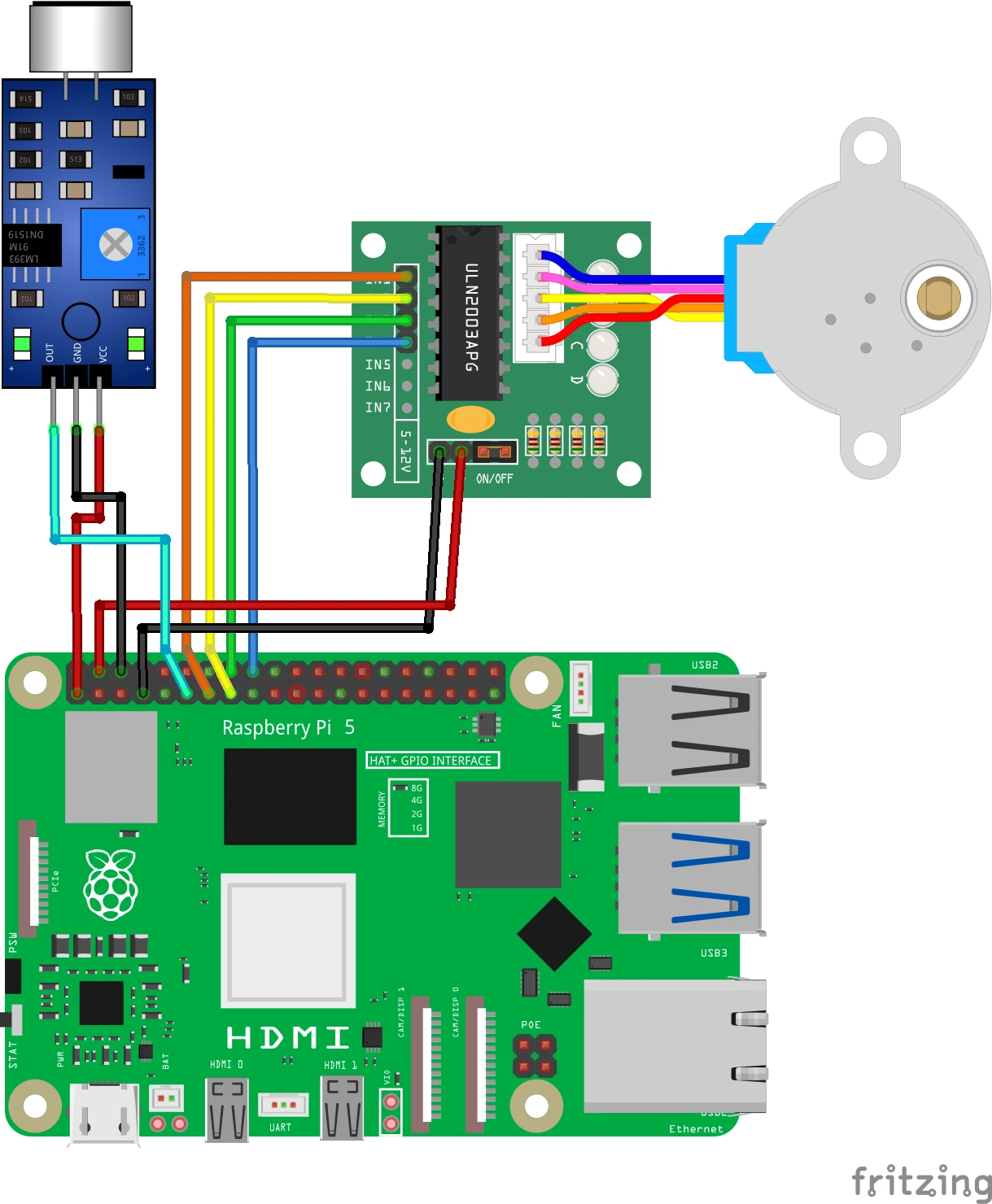

Connection diagram

Connect the sound sensor:

- VCC : Connect to 3.3V (pin 1) .

- GND : Connect to GND (pin 6) .

- DO (digital output) : Connect to GPIO 17 (pin 11) .

Connect the ULN2003 driver to the stepper motor:

- Stepper Motor : Connect the stepper motor connector to the header of the ULN2003 driver.

- ULN2003 driver :

- IN1 : Connect to GPIO 27 (pin 13) .

- IN2 : Connect to GPIO 22 (pin 15) .

- IN3 : Connect to GPIO 23 (pin 16) .

- IN4 : Connect to GPIO 24 (pin 18) .

- VCC : Connect to 5V (pin 2) .

- GND : Connect to GND (pin 6) .

Pinout Reference

GPIO | Pin # | Function | Connection |

| GPIO 17 | Pin 11 | Digital input | Sound sensor DO |

| GPIO 27 | Pin 13 | Stepper motor | ULN2003 IN1 |

| GPIO 22 | Pin 15 | Stepper motor | ULN2003 IN2 |

| GPIO 23 | Pin 16 | Stepper motor | ULN2003 IN3 |

| GPIO 24 | Pin 18 | Stepper motor | ULN2003 IN4 |

| 3.3V | Pin 1 | Power supply | Sound sensor VCC |

| 5V | Pin 2 | Power supply | ULN2003 VCC |

| GND | Pin 6 | Earth (Ground) | Sound sensor and ULN2003 |

Python code in Thonny

Step 1: Write your code

Open the Thonny Python IDE and enter the following code:

import RPi.GPIO as GPIO

from time import sleep

from collections import deque

# Geluidssensor en motor-pinnen

IN1 = 17

IN2 = 27

IN3 = 22

IN4 = 23

SOUND_SENSOR_PIN = 24

# GPIO instellen

GPIO.setmode(GPIO.BCM)

GPIO.setup(SOUND_SENSOR_PIN, GPIO.IN) # Geluidssensor als input

GPIO.setup(IN1, GPIO.OUT)

GPIO.setup(IN2, GPIO.OUT)

GPIO.setup(IN3, GPIO.OUT)

GPIO.setup(IN4, GPIO.OUT)

# Stepper motor sequentie (4-fase stappen)

step_sequence = [

[1, 0, 0, 0],

[1, 1, 0, 0],

[0, 1, 0, 0],

[0, 1, 1, 0],

[0, 0, 1, 0],

[0, 0, 1, 1],

[0, 0, 0, 1],

[1, 0, 0, 1]

]

# Instellingen voor piekdetectie

HISTORY_SIZE = 10 # Hoeveel metingen we bijhouden

THRESHOLD = 7 # Aantal HIGH's in HISTORY_SIZE om als piek te zien

MINIMUM_ACTIVE_TIME = 1 # Minimal actief blijven (seconden)

# Historie van geluidmetingen

sound_history = deque([1] * HISTORY_SIZE, maxlen=HISTORYSIZE)

def set_step(w1, w2, w3, w4):

"""Stel de status van de motorpinnen in."""

GPIO.output(IN1, w1)

GPIO.output(IN2, w2)

GPIO.output(IN3, w3)

GPIO.output(IN4, w4)

def step_motor(steps, delay):

"""Draai de motor een aantal stappen."""

for _ in range(steps):

for step in step_sequence:

set_step(*step)

sleep(delay)

try:

while True:

# Lees de huidige status van de geluidssensor

current_state = GPIO.INPUT(SOUND_SENSOR_PIN)

# Voeg de huidige meting toe aan de historie

sound_history.append(current_state)

# Tel hoeveel keer HIGH (1) in historie

low_count = sound_history.count(0)

# Controleer of er een piek is

if low_count >= THRESHOLD:

print("Piek in geluid gedetecteerd! Steppermotor draait.")

step_motor(512, 0.002) # Draai 512 stappen vooruit

sound_hitory.clear() # Reset de historie na een plek

sound_history.extend([1] * HISTORY_SIZE) # Vermijd snelle heractivatie

sleep(MINIMUM_ACTIVE_TIME) # Zorg dat de motor niet constant triggert

sleep(0.01)

except KeyboardInterrupt:

print("\nProgramma gestopt.")

finally:

GPIO.cleanup() # Reset de GPIO-instellingen

Step 2: Save the file

Click File > Save As and name the file sound_controlled_motor.py .

Step 3: Run the script

Click the green Run button (▶) at the top of the Thonny interface.

How does it work?

- Sound sensor:

- The sensor detects sounds such as clapping and sends a high signal (HIGH) to GPIO 17.

- Stepper motor:

- Once sound is detected, the motor will rotate 512 steps (forward).

- Adjust speed and steps:

- Adjust the value of delay and steps in the step_motor() function to change the speed and distance of the motor rotation.

Result

- Sound Detected : The stepper motor rotates one full rotation (512 steps).

- No sound detected : The motor remains silent.

Experimenting

- Adjust direction:

- Make the motor run backwards by reversing the order of the step_sequence list.

- Using light or other sensors:

- Replace the sound sensor with another input, such as an LDR or a push button.

- Add blinking LED:

- Add an LED that flashes when the engine is running.