5183+ reviews

Order by 16:00 for same day shipping

14 days return

EN

Individual

Business

Filters

Price

to

Tools

Whether you are a beginner or an experienced maker, good tools make all the difference. Bad tools slow down your work and cause frustration. Quality tools ensure speed, precision and fun. You work more safely and make fewer mistakes. In our range you will find everything you need for electronics and prototyping. Think of soldering irons, tweezers, multimeters and tools such as third hands.

75 products found

Sort by:

Three types of tools

In the world of electronics there are three types of tools: soldering, measuring and hand tools.

Soldering tools are the foundation. They are used to make connections between components and printed circuit boards. You will need a soldering iron, plus solder, paste and a holder. A solder sucker helps remove excess solder. Cleaning sponges ensure a clean tip and better soldering.

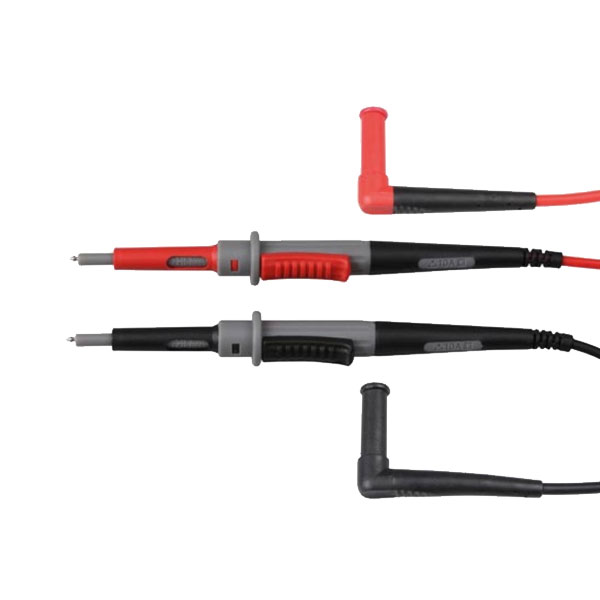

Measuring and testing equipment is indispensable. A multimeter measures voltage, current and resistance. For digital signals you use a logic analyzer or an oscilloscope. These provide insight into what is happening within your circuit.

Hand tools make working with small parts easier. Fine screwdrivers, cutting pliers and tweezers are essential. Do you work with microcontrollers or small sensors? Then precision is extra important. Additional tools such as a third hand or a magnifying glass with LED light help with this.

How do you choose the right tool?

Choose your tools based on your experience, your projects and your budget.

Are you just starting out? Then a simple set will suffice. A soldering iron, a basic multimeter and some hand tools will be enough. This way you can learn the basics without spending too much money.

Have you been working with electronics for a while? Then choose better tools. A temperature-controlled soldering station gives you more control. Antistatic tweezers protect sensitive components. A good oscilloscope makes complex signals visible. Durable tools last longer and work more pleasantly.

Pay attention to comfort and quality. A soldering iron with a nice grip and fast heating makes your work easier. Good quality tools remain reliable, even after a lot of use. Also look at reviews and experiences of other users.

Also think about safety. Work on a heat-resistant mat. Use antistatic materials to protect sensitive components. And make sure your tools are appropriate for your projects. Someone who works with SMD components needs different tools than someone who only builds large printed circuit boards.

Create a smart workplace

A good workspace saves time and prevents mistakes. Use a soldering mat to protect your table. Make sure there is enough light. A lamp with a magnifying glass is ideal for small parts.

Keep your work area tidy. Put tools back in their place after use. Clean soldering points with a sponge or brass shavings. Calibrate your measuring equipment regularly. This will keep your measurements accurate.

Good maintenance extends the life of your tools. You work better, avoid frustration and get the most out of every project. So invest in good tools and a smart workplace. It makes every project more fun and successful.