5169+ beoordelingen

Voor 16:00 besteld = dezelfde dag verzonden

14 dagen retour

NL

Particulier

Zakelijk

Filters

Prijs

tot

Solderen

Solderen is een onmisbare vaardigheid in elektronica en metaalbewerking. Je verbindt metalen onderdelen met soldeer, een legering die sneller smelt dan het materiaal zelf. Zo blijven de onderdelen onbeschadigd, maar stevig verbonden. Werk je aan een Arduino-project of soldeer je jouw eigen printplaten? Dan is goed kunnen solderen goud waard. In het begin lijkt het misschien lastig, maar met het juiste gereedschap en wat oefening krijg je het snel onder de knie. Dan wordt het een vaste techniek die je in veel projecten zult gebruiken.

63 producten gevonden

Sorteren op:

Wat is solderen?

Solderen verbindt twee metalen delen met gesmolten soldeertin. Dit tin is meestal een mengsel van tin en soms lood of zilver. Door verhitting smelt het tin en bij afkoeling ontstaat een sterke, geleidende verbinding. In elektronica gebruik je soldeer om onderdelen op een printplaat te bevestigen. Denk hierbij aan weerstanden, sensoren en connectoren.

Je gebruikt een soldeerbout om het tin te smelten. Verwarm altijd tegelijk de draad én het koperpad op de printplaat. Breng daarna pas het soldeer aan op de verbinding, niet op de bout. Zo vloeit het tin netjes tussen de metalen delen. Een goede soldeerverbinding is glanzend en bolvormig. Is het dof of bobbelig? Dan heb je waarschijnlijk een ‘cold joint’, een slechte verbinding die storing kan geven.

Timing is belangrijk. Verwarm je te kort, dan vloeit het tin niet goed. Te lang? Dan beschadig je onderdelen of de printplaat. Dit leer je door te doen. Met elk project krijg je meer gevoel voor timing en techniek.

Welk soldeergereedschap heb ik nodig?

De basis begint met een soldeerbout of soldeerstation. Een eenvoudige bout is prima voor kleine klussen. Een station met temperatuurregeling geeft meer controle. Vooral bij fijn werk of loodvrij solderen (wat een hogere temperatuur vraagt) is dat handig.

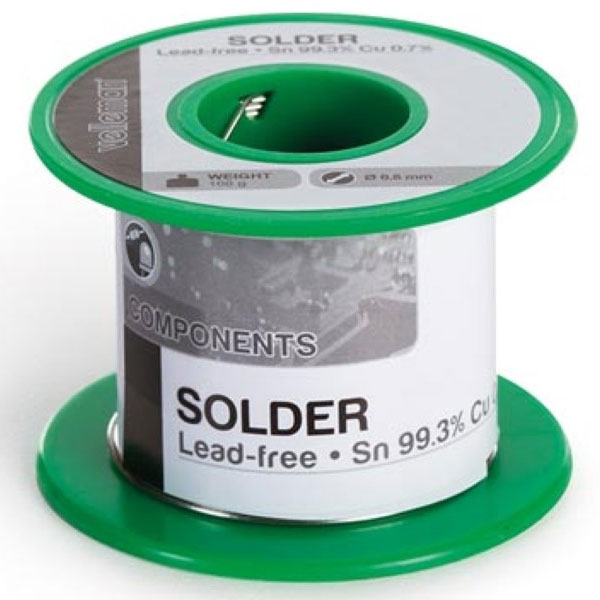

Gebruik altijd soldeertin. Je hebt de keuze tussen loodhoudend en loodvrij. Loodhoudend vloeit beter, wat prettig is voor beginners. Toch kiezen veel mensen voor loodvrij vanwege het milieu. Let ook op de dikte van het draad. Voor fijne elektronica is dunner soldeer makkelijker. De meeste soldeertin bevat flux. Flux is een hars die oxidatie voorkomt en het vloeien verbetert.

Handige extra’s zijn onder meer een pincet of ‘third hand’. Daarmee houd je onderdelen op hun plek tijdens het solderen. Een soldeerpomp helpt je bij het herstellen van fouten of verwijderen van oud tin. Houd de punt van je soldeerbout schoon met een sponsje of messing tip cleaner. Dat zorgt voor betere warmteoverdracht en netter werk.

Denk ook aan veiligheid. Solderen produceert rook, vooral door de flux. Werk dus in een goed geventileerde ruimte of gebruik een kleine afzuiger. Een hittebestendige soldeermat beschermt je tafel. Een veiligheidsbril is handig in kleine ruimtes waar je dicht op het werk zit.

Tips voor beter solderen

Begin rustig en nauwkeurig. Laat je soldeerbout eerst goed warm worden. Verwarm dan tegelijk het draadje en het koperpad. Voeg daarna pas het soldeer toe. Gebruik niet te veel: een klein beetje is vaak al genoeg. Laat de verbinding na het solderen stil liggen zodat het netjes kan uitharden.

Maak geen beginnersfouten. Houd het soldeer nooit direct tegen de bout. Dan smelt het te snel en vloeit het niet goed tussen de delen. Zorg ook voor schone onderdelen. Vuil of oxidatie zorgt voor slechte verbindingen. Maak dus je soldeerpunt en werkvlak regelmatig schoon.

Oefen! Met een oefenprint of soldeerkit leer je snel bij. Hoe vaker je soldeert, hoe beter je wordt. Je merkt dat je verbindingen netter en betrouwbaarder worden.

Wat kun je solderen?

Met solderen kun je alle kanten op. Je maakt er simpele schakelingen mee, zoals een knipperende LED of een geluidssensor. Werk je met een Arduino of Raspberry Pi? Dan kun je sensoren en modules stevig verbinden met een prototypeboard. Ook losse kabels en connectoren repareer je makkelijk met een soldeerbout.

Voor gevorderden is er SMD-solderen. Daarmee soldeer je piepkleine onderdelen direct op het oppervlak van de printplaat. Zo bouw je compacte en professionele apparaten.

Of je nu net begint of al verder bent: met goed gereedschap en een beetje oefening kun je eindeloos veel leuke en nuttige projecten maken.